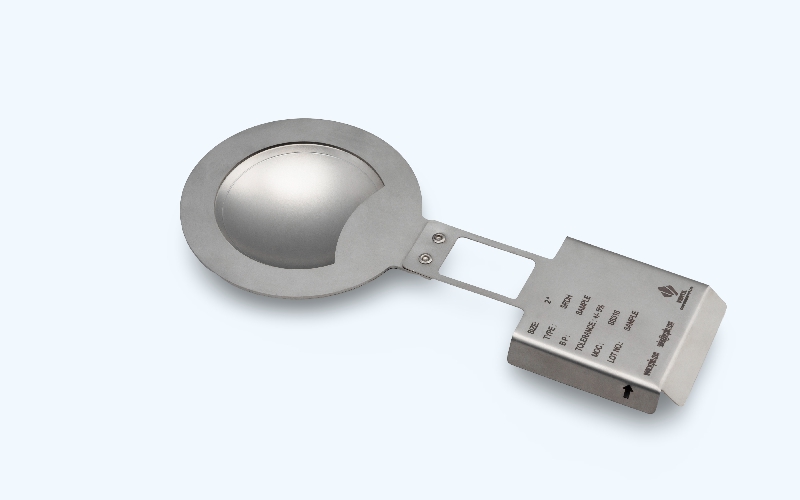

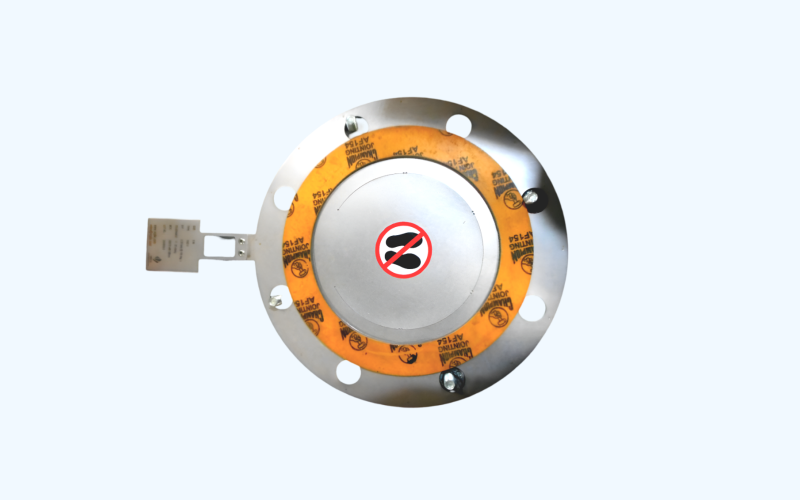

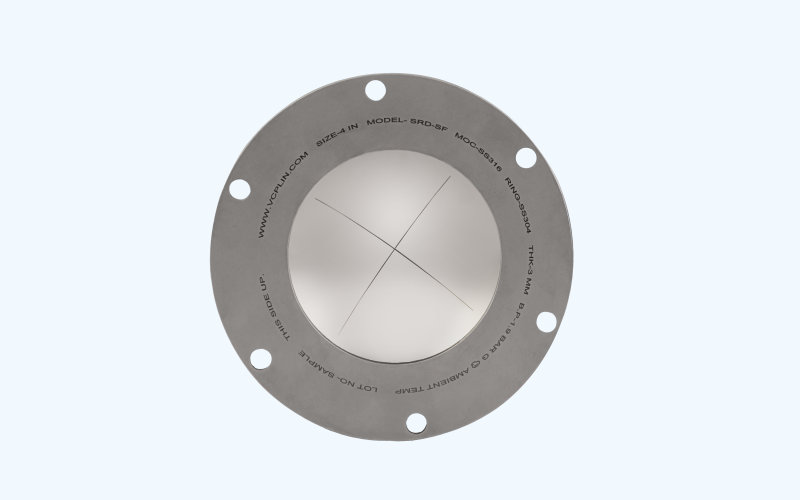

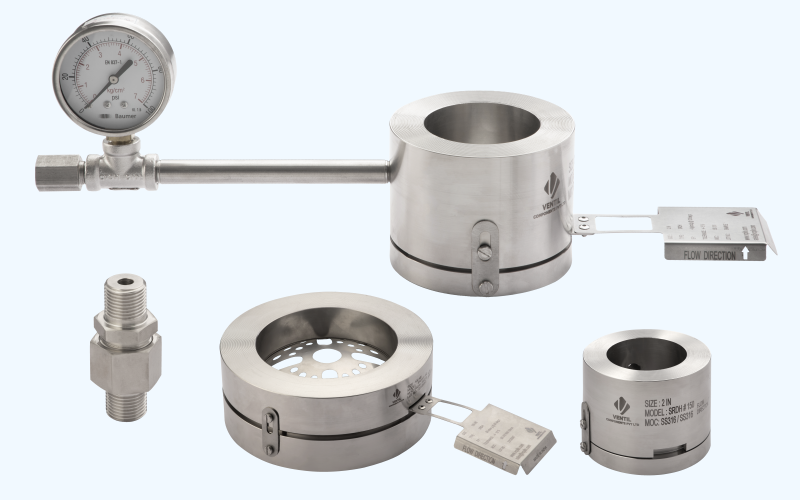

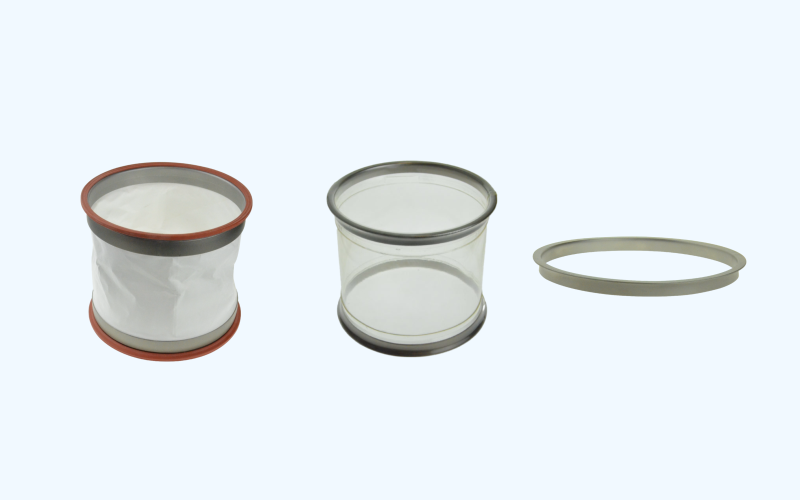

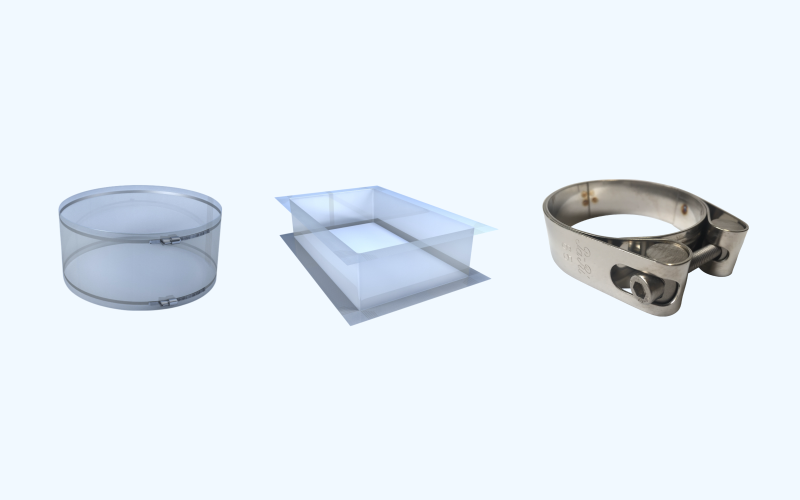

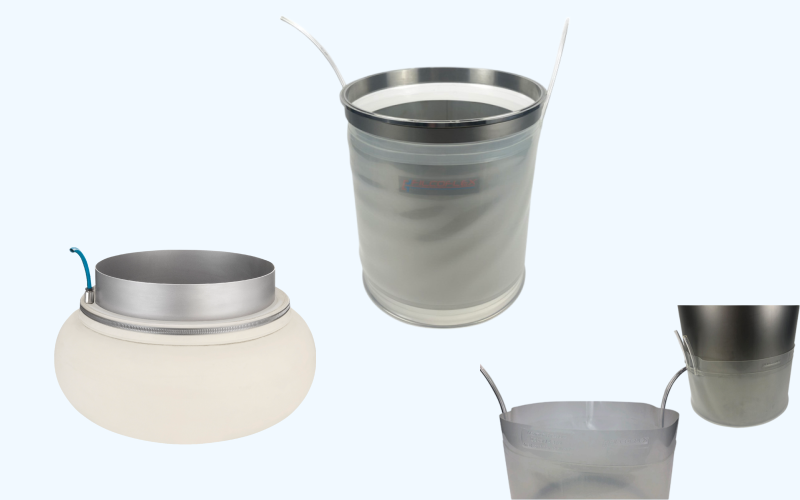

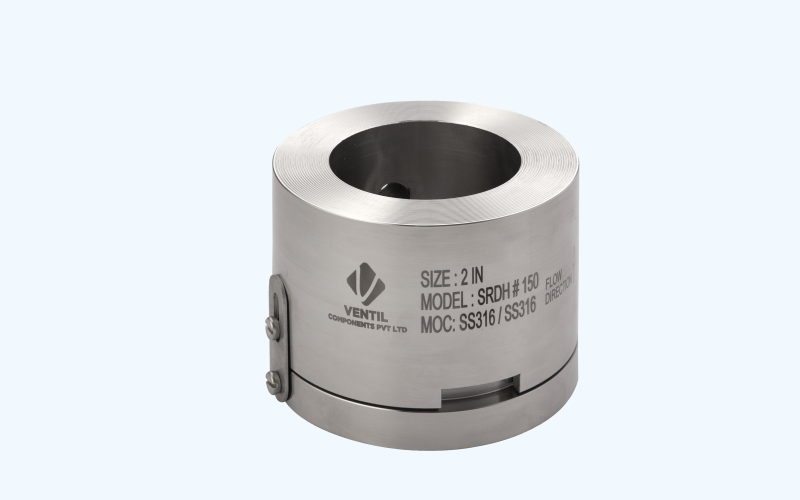

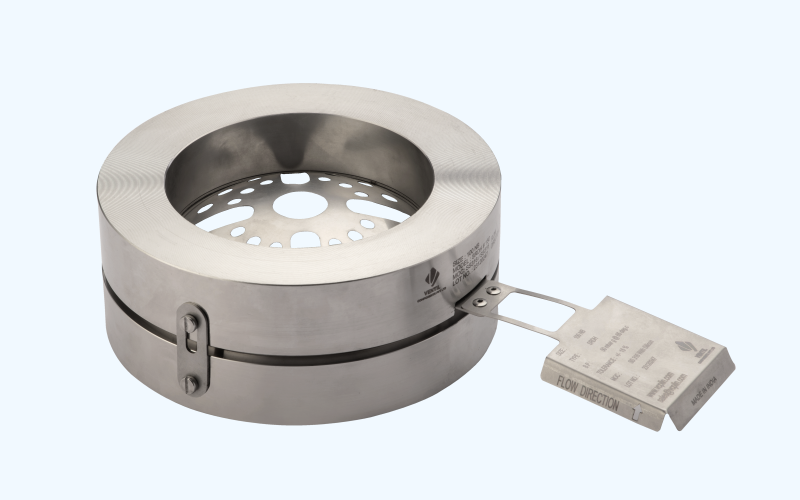

Sanitary Scored Reverse (SSR)

SSR is reverse acting, scored rupture discs for use in sanitary applications. The discs are designed for higher performance and operating parameters. The discs are suitable for use in Liquid and gas service. The discs are designed to fit directly in ASME BPE Ferrules or NA connects and don’t require any special holder / safety head of installation.