Guaranteed Safety

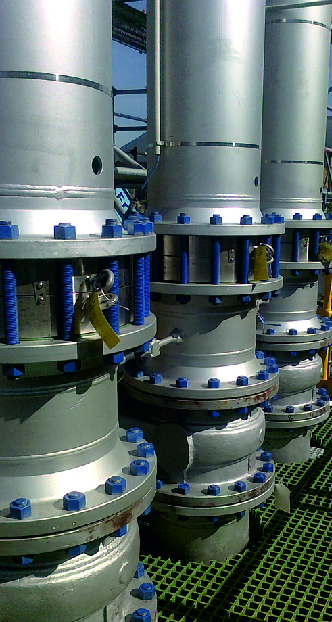

Welcome to Ventil Components Pvt. Ltd. a leading name among rupture disc manufacturers. We specialize in designing, manufacturing, and supplying high-quality rupture discs, also known as burst discs, for a wide range of industrial applications. With 15+ years of expertise, we ensure safety and reliability with every product we deliver.

When it comes to safeguarding your operation from overpressure, our rupture discs are your top choice. Designed with versatility and cost-effectiveness in mind, our discs adapt seamlessly to a wide range of applications.

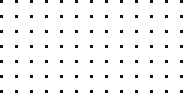

A Rupture Disc (also known as a burst disc or pressure relief disc) is a critical safety device used in pressurized systems to protect against overpressure or vacuum conditions. Designed to "burst" at a specified pressure, rupture discs provide an immediate and fail-safe solution to prevent equipment damage or catastrophic failure.

The rupture disc working principle is straightforward: the disc is installed in a system to act as a barrier. When the system pressure exceeds the disc’s specified burst pressure, it breaks open, allowing pressure to escape. This simple yet effective mechanism prevents damage and ensures safety.

Looking for premium rupture discs or need advice on rupture disc sizing? Get in touch with Ventil Components Pvt. Ltd., the trusted rupture disc manufacturers for all your pressure relief needs. Contact us today to learn more about our products and services.

Call Us Anytime:

+9156463116Email Us:

sales@vcplin.com

We engineer products specifically for your system — no matter what industry you work in.

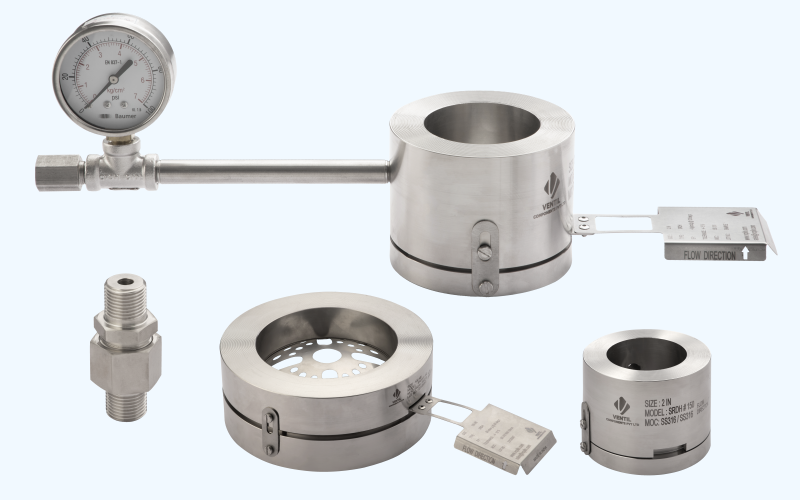

SSR is reverse acting, scored rupture discs for use in sanitary applications. The discs are designed for higher performance and operating parameters. The discs are suitable for use in Liquid and gas service. The discs are designed to fit directly in ASME BPE Ferrules or NA connects and don’t require any special holder / safety head of installation.

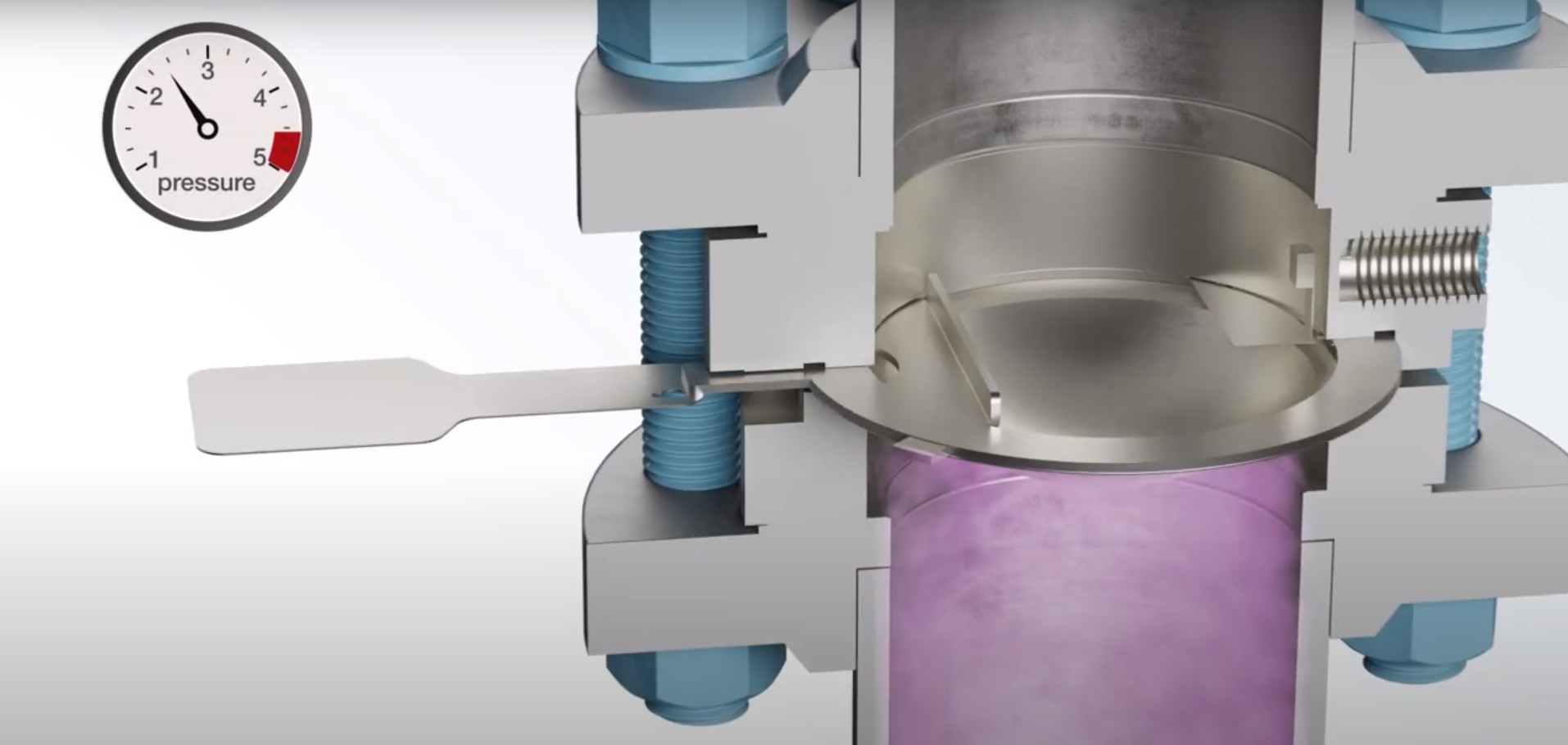

Scored Reverse Acting Rupture disc functions when the pressure creates an instability in the dome, resulting in reversal, or buckling, of the dome. Typically, have longer cycle life than forward-acting designs because reverse-acting discs' stresses are compressive in nature.

Flat atmospheric Disc: FAD is used for protection against overpressure, e.g. in storage vessels, tanks, pipeline and low-pressure systems. Also suitable as a secondary safety device alongside safety valves. This rupture disc is designed to work at standard operating ratios of up to 50-60% of the burst pressure. Due to non-asbestos gaskets installation is leak free in the flanges.

Composite Dome -Forward Acting Rupture disc design, the loads are applied to the concave side of the rupture disk, stretching the dome until the tensile forces exceed the ultimate tensile stress of the material and the disk bursts. A versatile, flat-seat, composite rupture disc that can act as an environmental seal, corrosion barrier, or isolate the downstream side of low-pressure storage vessels. This rapture disc are also available with holder.

SSR is reverse acting, scored rupture discs for use in sanitary applications. The discs are designed for higher performance and operating parameters. The discs are suitable for use in Liquid and gas service. The discs are designed to fit directly in ASME BPE Ferrules or NA connects and don’t require any special holder / safety head of installation.

Some Rupture discs require Holders are required for Rupture discs to ensure proper installation and performance. Based on the burst pressure of Rupture discs, the Holders are designed to install in between standard flanges. Flange ratings can be ANSI, DIN or ISO flanges as per customer requirements. We also have threaded holders for smaller sizes like 1⁄4” , 1⁄2” and 1”. Standard MOC available is SS 304 or SS 316. Other material available on request.