What is an Explosion Vent ?

An explosion vent is a safety device designed to protect industrial equipment by relieving excess pressure caused by explosions. These vents prevent catastrophic damage by safely directing explosion energy away from machinery and personnel.

How Do Explosion Vents Work?

Explosion vents are designed to rupture at a predetermined pressure, allowing gases and flames to escape safely. They are commonly used in industries dealing with combustible dust, gases, and chemicals, reducing the risk of equipment failure and workplace hazards.

Benefits of Using Explosion Vents :

- Prevents Equipment Damage : Reduces pressure buildup and protects machinery.

- Enhances Workplace Safety : Minimizes the risk of explosions harming workers.

- Cost-Effective Solution : Compared to other explosion protection systems, vents are an economical choice.

- Compliance with Safety Standards : Meets NFPA and ATEX regulations for industrial explosion protection.

Industries That Require Explosion Vents :

Explosion vents are crucial in industries handling flammable dust, gases, and chemicals, including:

- Food Processing : Grain silos, sugar processing, flour mills.

- Pharmaceuticals : Powder processing, chemical reactions.

- Chemical Manufacturing : Solvent vapors, flammable gases.

- Power Plants : Coal dust, biomass energy production.

- Metalworking : Aluminum and magnesium dust handling.

- Safety Equipment Manufacturers : Providing safety protection and safety equipment for industries.

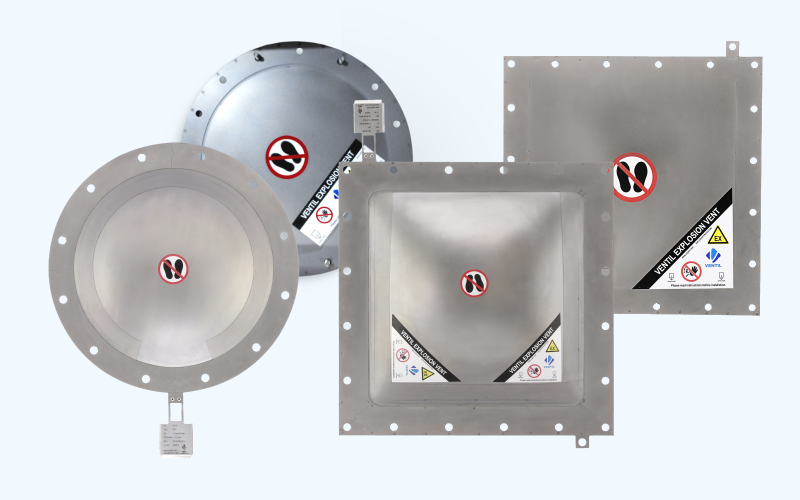

Types of Explosion Vents :

- Domed Explosion Vents :

- Features a convex (domed) shape to handle high internal pressures.

- Constructed from stainless steel, aluminum, or reinforced materials for durability.

- Available with vacuum support to withstand negative pressure conditions.

- Composite Explosion Vents :

- Built with multiple layers of materials (metallic and non-metallic) to provide controlled venting.

- Features a weakened membrane that bursts at a predetermined pressure.

- Some models include a backup vent for added protection in case of secondary explosions.

How to Choose the Right Explosion Vent :

When selecting an explosion relief vent, consider:

- Explosion Vent Design : Ensures optimal performance based on application.

- Explosion Vent Sizing : Correctly calculated for specific industrial requirements.

- Operating Pressure & Temperature : Ensure compatibility with your system.

- Material & Coating : Stainless steel or composite panels for corrosion resistance.

- Application-Specific Needs : Custom explosion vents may be required for unique setups.

- Compliance with Safety Standards : NFPA, ATEX, or OSHA compliance.

Installation and Maintenance of Explosion Vents :

Proper installation and maintenance of explosion vents ensure longevity and safety:

- Correct Sizing : Based on pressure relief requirements.

- Proper Placement : To direct explosion energy away from critical areas.

- Regular Inspections : To detect any wear or damage.

- Replacement Schedule : Periodic replacement as per manufacturer guidelines.

Ventil - The Best Explosion Vent Manufacturers & Suppliers in India

If you're looking for high-quality explosion vents, Ventil is the leading explosion vent manufacturers in India that offer customized solutions for different industries. Some key factors to check.

Conclusion

At Ventil, we understand the importance of industrial safety and reliable explosion protection solutions. Our explosion vents, explosion relief panels, and rupture panels are engineered to provide maximum safety while meeting industry standards. Whether you operate in food processing, pharmaceuticals, power plants, or chemical manufacturing, choosing the right explosion venting solution is essential for compliance and safety.

For expert advice on selecting the best explosion vent panel, rupture panel, or explosion relief panels for your industry, consult Ventil, your trusted explosion vent manufacturer and supplier, today!