What is Flameless Explosion Venting?

Flameless explosion venting is an advanced industrial safety solution that protects facilities from dust explosions and combustible dust hazards. It effectively dissipates explosion pressure while preventing flames and hot gases from escaping into the workplace. Our flameless venting device ensures compliance with NFPA explosion venting standards, ATEX-certified explosion vents, and OSHA regulations to safeguard equipment and personnel.

Why Choose Flameless Explosion Venting?

Industries dealing with combustible dust explosion risks require high-performance explosion venting solutions to prevent catastrophic damage. Our flameless venting system offers:

- Flame Containment : Prevents fire spread within enclosed spaces.

- Pressure Relief Explosion Venting : Reduces structural damage.

- Industrial Air Filter Integration : Ensures clean and safe working conditions.

- Safe for Indoor Explosion Venting Applications : No need for external venting ducts.

- Compliance with Industrial Explosion Safety Standards : Meets NFPA, ATEX, and OSHA regulations.

- Protects Workers and Equipment : Minimizes explosion hazards in factories and processing plants.

Industries That Require Flameless Explosion Venting :

Flameless explosion vents are essential in industries prone to dust explosion hazards, including:

- Food Processing : : Explosion venting for grain, sugar, and flour dust

- Pharmaceutical Manufacturing : Dust explosion venting for powder handling systems.

- Chemical Industry : Explosion safety solutions for hazardous dust particles.

- Metal and Recycling Plants : Flameless venting devices for fine metal dust.

- Woodworking and Paper Mills : Dust explosion protection for sawdust and paper dust collection systems.

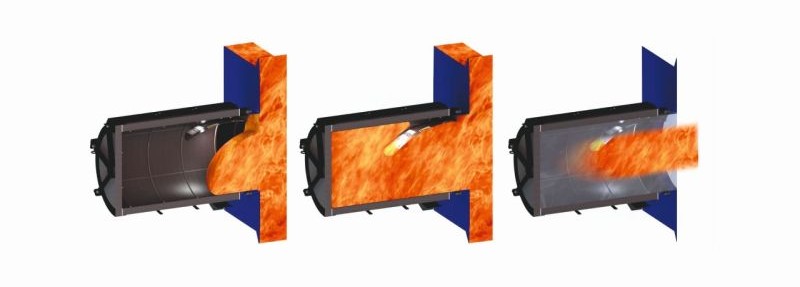

How Does Flameless Venting Work?

Flameless venting is a critical safety mechanism designed to protect industrial equipment and personnel from dust explosions, especially in enclosed environments where traditional venting could be hazardous. Here's how it works:

1. Explosion Occurs :

- During certain industrial processes, combustible dust or gas may ignite due to heat, friction, or a spark.

- This ignition leads to a rapid pressure increase inside the enclosed equipment, creating a potentially dangerous explosion.

2. Vent Opens :

- To prevent structural damage, the explosion vent panel (also known as a burst panel) is designed to open at a predetermined pressure.

- This opening allows the overpressure and flame to escape in a controlled manner, relieving the pressure inside the vessel or duct.

3. Flames Extinguished (Flameless Discharge) :

- As the hot gases and flames exit, they pass through a stainless steel mesh or flame arrestor.

- This mesh rapidly cools the hot gases, quenching the flames instantly.

- Only harmless, de-energized gas is released into the surrounding area, eliminating the risk of secondary explosions or injuries caused by open flames.

Key Features of Flameless Explosion Vents :

Rupture discs are vital safety devices across various industries, ensuring operational safety and efficiency. Below are some common applications:

- Compact and easy installation : Ideal for indoor explosion venting applications

- Industrial filtering compatibility : Works with industrial air filters for enhanced safety.

- Maintenance-free operation : Durable and long-lasting design.

- Effective dust Explosion Mitigation : Works with dust collectors, silos, and processing units.

Get the Best Flameless Explosion Venting System for Your Industry!

Ensure safety and compliance with our high-performance explosion venting solutions. Contact us today for expert guidance on choosing the right industrial explosion protection system for your facility.

At Ventil, we provide high-quality industrial explosion protection systems, including flameless explosion venting, explosion relief vents, and explosion suppression systems. Our ATEX - certified explosion vents ensure maximum safety and compliance with explosion protection guidelines.