Introduction :

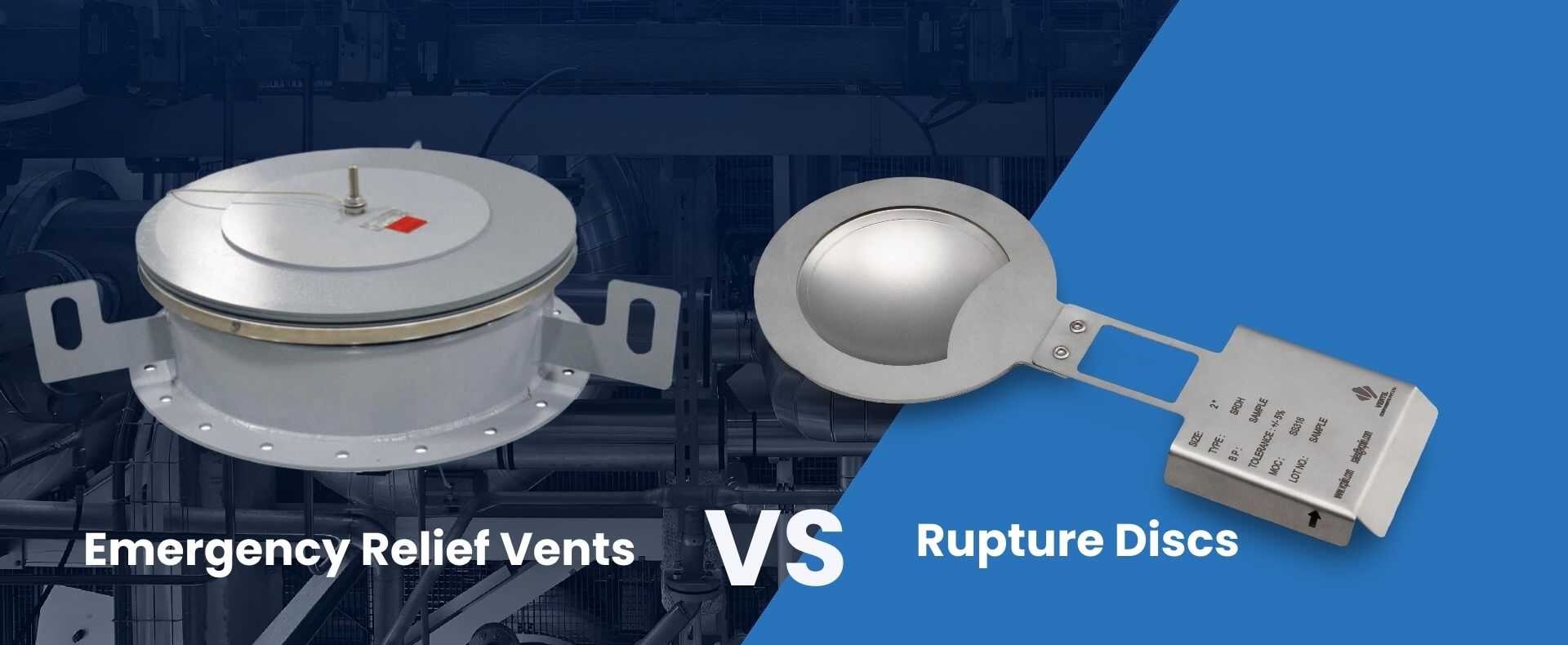

Industrial facilities face serious risks from overpressure events like explosions or equipment failure. To prevent disasters, two critical solutions are commonly used: emergency relief vents and rupture discs. While both protect against pressure buildup, they work differently and suit different applications.

In this guide, we'll compare emergency vents and rupture discs to help you choose the right protection for your operation — ensuring safety, compliance, and system reliability.

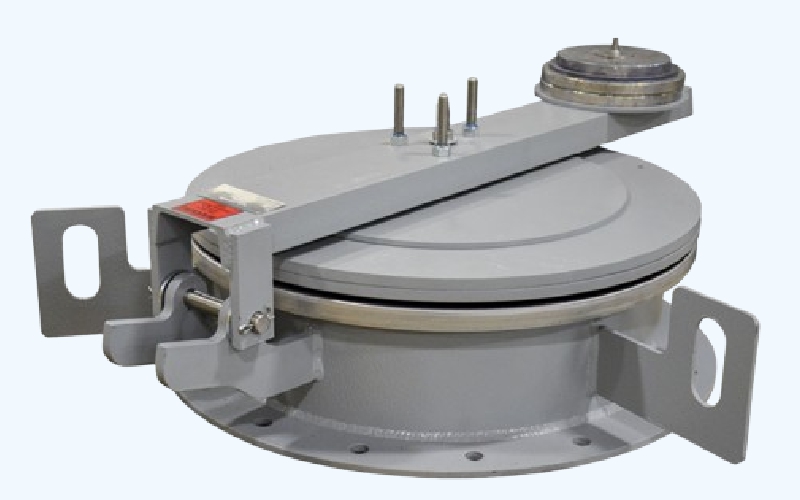

What Are Emergency Relief Vents?

- Devices that rapidly open to relieve sudden pressure build-ups, especially from explosions.

- Applications: Dust collectors, grain silos, chemical storage tanks.

- Key Features:

- Lightweight design for fast reaction.

- Can often be reset after activation.

- Compliant with NFPA 68 for explosion venting.

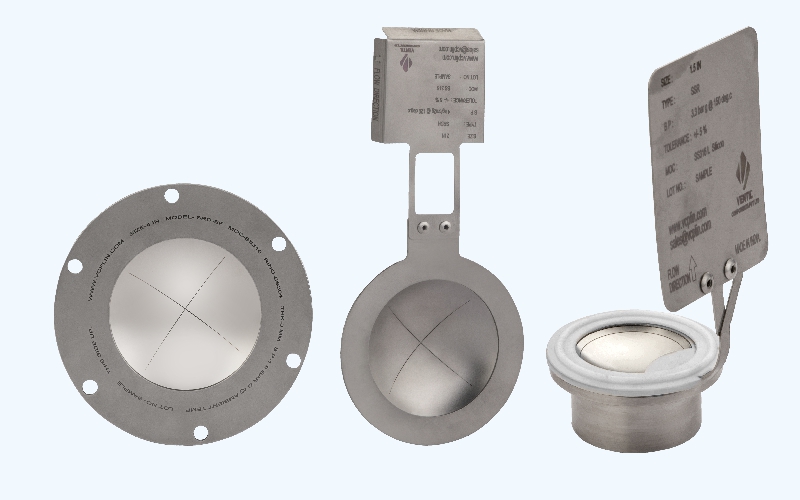

What Are Rupture Discs?

- Single-use devices that burst at a specific pressure to protect equipment from catastrophic failure.

- Applications: Pressure vessels, reactors, pipelines, pharmaceutical processing.

- Key Features:

- Ultra-fast response to overpressure events.

- No moving parts — maintenance-free.

- Compatible with ASME and PED standards.

Key Differences: Emergency Relief Vents vs. Rupture Discs

| Feature | Emergency Relief Vents | Rupture Discs |

|---|---|---|

| Operation | Opens under pressure, resealable models available | Bursts at predetermined pressure |

| Speed | Fast for explosions | Instantaneous burst |

| Reusability | Some reusable | Single-use only |

| Best For | Dust explosion, deflagration control | Liquid/gas overpressure, chemical containment |

| Certifications | NFPA 68, OSHA | ASME Section VIII, PED, ISO |

When to Choose an Emergency Relief Vent :

Use emergency relief vents when:

- Dealing with combustible dust hazards.

- Protecting low-pressure storage vessels like bins, silos, or dust collectors.

- Needing compliance with NFPA 68 and OSHA explosion protection standards.

- Resetting the system quickly after an event matters.

When to Choose a Rupture Disc

Use rupture discs when:

- Protecting high-pressure vessels and piping systems.

- Working with toxic or corrosive gases and liquids.

- Needing a zero-leakage pressure protection solution.

- Pairing with pressure relief valves (PRVs) for system redundancy.

Can Emergency Vents and Rupture Discs Work Together?

- Yes! Many industries layer protection using both.

- Example: A rupture disc installed upstream of an explosion vent.

- Advantages: Enhanced safety, compliance with multi-layer protection codes.

Final Decision: Which Is Best for Your Facility?

- Choose emergency relief vents for dust explosions and low-pressure venting.

- Choose rupture discs for high-pressure containment and precision overpressure protection.

- Always consult safety standards like NFPA 68, ASME, and OSHA before choosing.

📞 Need Help Selecting the Right Protection?

Choosing between an Emergency Relief Vent and a Rupture Disc depends on your process, pressure levels, and safety requirements. Contact Ventil today for a free system assessment. Our experts will help you select, size, and install the right emergency relief vents or rupture discs for your specific needs.